Digitmakers.ca

Filaments Depot Blue PLA 3D850 1kg

Filaments Depot Blue PLA 3D850 1kg

- Made with recyclable spool and box

- Includes an extra resealable bag in the box

- Printing Temperature : 205°C - 215°C

- Heated Bed: PLA can be printed with or without a heated print bed, however, if your 3D printer does have a heated bed, it is recommended that you set your bed temperature to approximately 55°C-60°C.

- First layer usually 5°C-10°C higher than subsequent layers.

- Sticks well to Glass with PVA Glue ,BuildTak, PEI, or blue tape.

- Cooling Fan: Highly recommended.

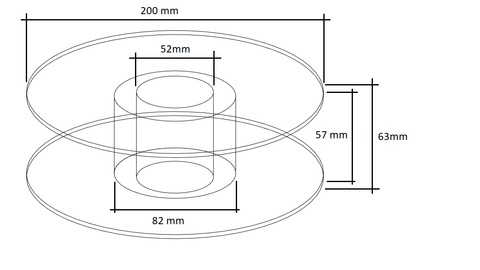

- Empty Spool Weight : 140 Grams

- Gross Weight :1140-1170 Grams

- Net Weight : 1KG

- Tensile Yield Strength, psi (MPa) 7,440 (51)

- Tensile modulus, psi (MPa) 335,790 (2315)MPa

- Tensile strength, psi (MPa) 7,290 (50)MPa

- Elongation % 3.31

- Notched Izod Impact, ft-lb/in (J/m) 2.21 (118)

- Heat Distortion Temperature (°C) 66 psi (0.45 MPa) 80-90

Annealing (Heat Treating) Instructions

-

Preparing the part: Ensure that your 3D printed part is clean and free from any support structures or debris.

-

Oven setup: Set up an oven or a heat source capable of reaching the required annealing temperature. Check the manufacturer's guidelines or the material datasheet to determine the recommended annealing temperature for 3D850 filament. Typically, for 3D850, the annealing temperature ranges between 80 to 110 degrees Celsius (176 to 230 degrees Fahrenheit).

-

Heat the part: Place the 3D printed part on a heat-resistant tray or a ceramic plate and put it inside the oven. Make sure the part is adequately supported and does not deform during the process.

-

Annealing process: Gradually increase the oven temperature to the recommended annealing temperature for 3D850. This should be done slowly to avoid any sudden temperature changes that could cause warping or cracking of the part. You can increase the temperature in increments of 10-15 degrees Celsius (18-27 degrees Fahrenheit) every 10-15 minutes until the desired annealing temperature is reached.

-

Soak at annealing temperature: Once the oven reaches the recommended annealing temperature, allow the part to soak at that temperature for a sufficient amount of time. The recommended soaking time can vary depending on the size and geometry of the part, but a general guideline is to keep it at the annealing temperature for at least 30 minutes to an hour.

-

Cooling process: After the soaking period, slowly cool down the part by reducing the oven temperature gradually. Avoid rapid cooling, as it may introduce stress or deformations in the part. You can turn off the oven and let it cool naturally inside or open the oven door slightly to facilitate cooling while ensuring a gradual temperature decrease.

-

Post-annealing inspection: Once the part has cooled down to room temperature, inspect it for any changes in dimensions, surface quality, or structural integrity. Annealing can help relieve internal stresses and improve the part's mechanical properties, but it's essential to verify if it meets your specific requirements.

Share

Subscribe to our emails

Be the first to know about new collections and exclusive offers.